In various industries, industrial flow control systems are important in the regulation of liquids and gases in oil and gas, power, water treatment and chemical processing sectors. Ball valves are highly favored among the other types of valves and are mainly used because of their tight shut-off, durability, and easy operation. The complexity of the industrial processes has enhanced the need to have an A dependable Ball Valve Manufacturer that is capable of providing precision engineered solutions. Regent Hitech private limited has become a household brand in this field due to the quality ball valves they provide that are suitable in the hard industrial circumstances. The company has high-tech levels of manufacturing and highly emphasizes on performance, which delivers efficient and safe flow control solutions throughout industries.

A Ball Valve Manufacturer is an experienced engineering company that deals with designing, developing and manufacturing of ball valves to be used in the industries. It is the role of these manufacturers to convert raw materials into components that are machined to a high degree of accuracy that will guarantee a consistent flow. They are not only required in production but also the engineering design, pressure analysis, material selection, and performance testing. There should also be accuracy where a slight variation will have repercussions on the sealing of the valves and service life. Oil & gas, chemicals, power generation and water management industries are some of the sectors which depend on experienced manufacturers to have the same quality. The professional manufacturers are making sure that valves are safe to use under high pressure, changes in temperature and corrosion conditions as well as meet application-specific specifications.

Regent Hitech Private Limited is the manufacturer of a broad variety of ball valves to suit the varied industrial flow control needs. The company is a veteran Ball Valve Manufacturer that provides high-quality designs that can fit different pressure ratings, type of media and conditions of operation.

These valves feature a compact, single-body construction, making them ideal for low-maintenance applications. They are commonly used in water, air, and general-purpose industrial systems.

Designed for easy maintenance, this valve allows inline servicing without pipeline removal, making it suitable for chemical and process industries.

PFA lining provides excellent resistance against corrosive chemicals, ensuring safe operation in aggressive environments.

Forged steel valves are built for high-pressure and high-temperature applications, offering superior strength and durability.

These valves combine robust flange connections with service-friendly design, ideal for critical industrial applications.

Regent Hitech Private Limited is a reputed firm dealing with manufacturing of industrial valves to both local and foreign markets. The firm has integrated technical know-how, state of the art infrastructure, and talented manpower to provide line-of-flow products of high reliability. Being one of the professional Ball Valve Manufacturer, Regent Hitech specializes in manufacture of valves that are efficient in performance, safety and endurance. The consistent investment in the technologies and the enhancement of the process is what enables the company to provide the same level of quality in all the products of the range. The key values that determine its operations are innovation, customer satisfaction, and global standards. Regent Hitech Private Limited has been able to become a reliable partner to industries requiring long term solutions to their valve requirements through effective production planning and high quality monitoring processes.

The production process in Regent Hitech Private Limited will be such that it produces strong and efficient ball valves. It starts with elaborate engineering and designing where specifications are made with reference to the needs of the application. The company has a long history of being a Ball Valve Manufacturer and therefore, the selection of raw materials is done with a lot of care so that it offers strength, resistance to corrosion and durability. A fine machining is done using the modern CNC machines to get the right dimensions and finishes. Components are controlled and assembled after machining to provide flawless assembly and sealing. All the valves are then put to strict tests which include pressure and leakage tests. Close quality control measures mean that all the valves are addressed to international performance as well as safety level before shipping.

One of the key factors of the ball valve operation and service life is the material choice. Regent Hitech Private Limited applies high grade materials that are applicable in various operating conditions. High pressures and high temperature are the applications where carbon steel ball valves are desired because of its strength. Stainless steel is mostly applied in corrosive conditions and hygienic facilities like food and pharmaceuticals. Alloy steel materials contain superior mechanical properties in the demanding industrial uses. Before a professional Ball Valve Manufacturer makes a decision on materials, he will consider the type of fluid, temperature, pressure and exposure to the environment. The application-oriented methodology guarantees maximum performance, safety, reliability of the valves in the long term.

At Regent Hitech Private Limited, valve manufacture is a basic component of quality assurance. The company adheres to internationally accepted standards in order to achieve product consistency and reliability. Being a certified Ball Valve Manufacturer, all the valves are inspected in terms of the dimensional checks, material checks, and pressure testing. Sealing efficiency and operational performance are tested using advanced testing methods. Industrial standard provides application appropriateness in sectors. Quality control processes are also enhanced by documentation and traceability. Through high standards of compliance with the world standards, Regent Hitech provides valves that satisfy the customer needs of safety, durability and efficiency of operation.

The Regent Hitech Private Limited products such as ball valves find application in diverse industries. They are used in oil and gas industry to regulate the flow of the high pressure fluids with safety and efficiency. Precision valves are required in chemical and petrochemical plants to work with corrosive and dangerous fluids. The ball valves are used in water treatment facilities to provide good isolation and regulate the flow. They are depended on to provide power plants with steam and utility uses. Flow control solutions that are hygienic and without contamination are needed in pharmaceutical and food industries. A dependable Ball Valve Manufacturer will make sure that valves will be able to work in all these harsh industrial conditions.

In order to achieve this the Ball Valve Manufacturer must be chosen in such a way that the reliability of operation is guaranteed over a long period. Regent Hitech Private Limited has the most modern manufacturing facilities with modern machinery and testing equipment. The company offers customization features to cater to particular uses of the applications. Its competitive pricing, stable quality and prompt delivery make it an option of choice by industrial clients. It also has a good value proposition on top of solid technical support and customer service. Regent Hitech is a reliable source of the industrial flow control solution due to its successful experience and focus on excellence.

Regent Hitech Private Limited has maintained the benchmarks in terms of manufacturing industrial valves by the use of precision engineering, quality material and rigorous testing of products. The company is a reputable Ball Valve Manufacturer and as such it provides dependable solutions that are to be expected to perform over a long term in arduous conditions. It has been able to maintain its reputation as a reliable manufacturing partner due to its commitment to innovation, quality, and customer satisfaction making its products reliable in controlling the flow in a wide range of industrial applications.

The 3 Piece Design Screwed End Socket Weld Ball Valve is a versatile and durable valve engineered for demanding industrial applications requiring secure shutoff, easy maintenance, and reliable flow control. With its three-piece body construction, this valve allows for convenient inline servicing without removing the entire valve from the pipeline, making it an ideal choice for systems that require frequent maintenance or where downtime needs to be minimized. The screwed end socket weld design ensures leak-proof connections and enhances overall durability, making it suitable for high-pressure and high-temperature environments.

The 3 Piece Design Screwed End Socket Weld Ball Valve is an excellent choice for industries needing a versatile, durable, and easy-to-maintain valve for high-pressure applications. Its robust construction, combined with flexible connection options and convenient inline maintenance capabilities, ensures reliable performance and cost-effective operation in various demanding environments.

Three-Piece Body Construction : The three-piece design allows for easy disassembly, maintenance, and cleaning without removing the valve from the pipeline, reducing downtime and operational costs.

Screwed End and Socket Weld Connections : The combination of threaded and socket weld connections provides secure and leak-proof installation options, allowing for flexibility in different piping systems.

Full Port Design : With a full bore opening, the valve provides unrestricted flow, minimizing pressure drop across the valve and ensuring efficient system performance.

High-Quality Sealing : The valve is equipped with advanced sealing components that provide a tight shutoff, preventing leaks and ensuring reliable operation in high-pressure applications.

Durable Materials : Constructed from corrosion-resistant materials such as stainless steel or carbon steel, the valve is suitable for handling a variety of fluids, including corrosive and abrasive media.

Easy Maintenance : The three-piece construction simplifies maintenance and repairs, allowing for the removal of the center section for cleaning or replacement without disturbing the piping connections.

| Valve Details: | |

|---|---|

| Model | BV-3P/D |

| Operation | lever / Phenumatic / Control Type |

| Size | 15 MM to 80 MM |

| Design | Investment casting, 3-piece design, full bore, blow-out proof stem, floating ball, soft-seated, non-fire safe design |

| Design & Mfg. Std. | BS 5351 (BS EN ISO 17292) |

| Inspection & Testing Std. | BS 6755 part i |

| Body | WCB / CF8 / CF8M / CF3M |

| Ball | AISI 304 / 316 / 316L |

| Seat Seal | PTFE / GFT |

| Working Temperature | Upto 180 - 2300 C |

| Working Pressure | as per 150# |

| End Connection | Screwed to BSP / BSPT / NPT, Socket Weld |

| Actuator Details: | |

|---|---|

| Method of Transmission | Double rack and pinion type |

| Actuation | Double acting - Air to open, air to close; fail-safe - Stay put |

| Body Material | Extruded aluminium, hard anodized |

| Caps and Rack | Aluminium, pressure die cast |

| Pinion | EN 8 |

| Seals | Buna-N |

| Air Pressure | Normal air supply: 5 kg/cm2 Max air supply: 7 kg/cm2 |

| Actuator Design | ISO 5211 (actuator can be quickly and easily mounted) |

| Rotation | 900 – Quarter turn |

Chemical and Petrochemical Processing : Ideal for handling a wide range of chemicals, hydrocarbons, and other corrosive fluids, the valve’s robust design and durable materials ensure long-term reliability.

Oil and Gas : Used in oil and gas pipelines for controlling the flow of crude oil, natural gas, and other fluids under high-pressure conditions. The valve’s secure connections and reliable sealing make it suitable for these demanding environments.

Pharmaceutical and Food Processing : The valve’s easy maintenance and corrosion-resistant materials make it suitable for hygienic applications, including food, beverage, and pharmaceutical processing, where frequent cleaning may be required.

Steam and Condensate Systems : Commonly used in steam and condensate systems due to its high-temperature tolerance and secure socket weld connections, providing efficient flow control in heating and cooling systems.

General Industrial Applications : Suitable for a variety of industries requiring a reliable valve for high-pressure applications, such as power generation, pulp and paper, and water treatment.

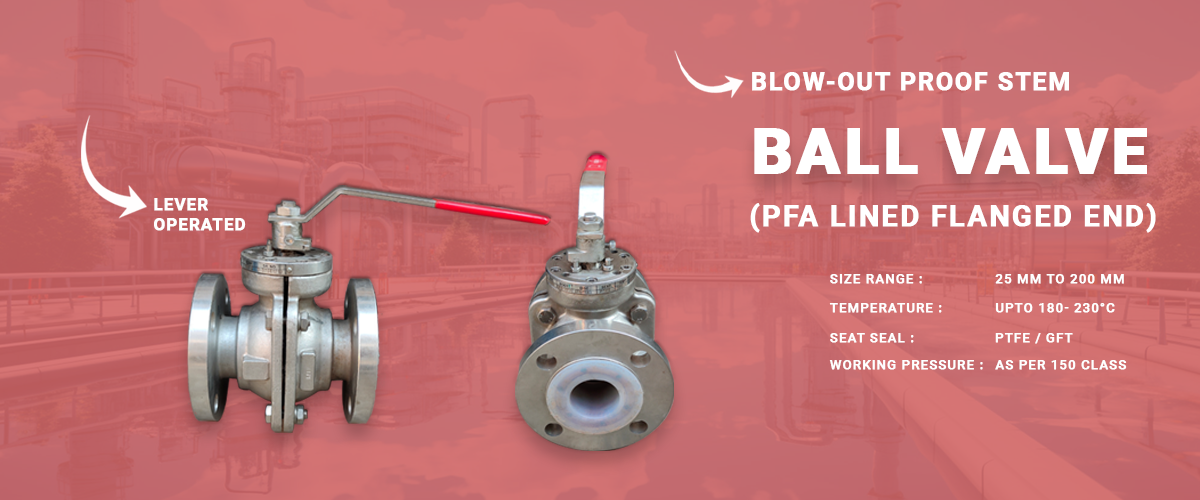

The PFA Lined Flanged Ball Valve is specifically designed for handling highly corrosive and aggressive chemicals in demanding industrial applications. This valve is lined with Perfluoroalkoxy (PFA), a high-performance fluoropolymer that provides excellent chemical resistance, ensuring safe and reliable flow control in challenging environments. The flanged end design enhances stability and leak-proof performance, making this valve an ideal choice for applications requiring superior corrosion protection and a secure, long-lasting connection to the piping system.

The PFA Lined Flanged Ball Valve is a robust and reliable solution for industries dealing with highly corrosive and hazardous chemicals. With its superior chemical resistance, durable construction, and secure flanged connections, this valve ensures safe, efficient, and long-lasting flow control in challenging environments, making it a preferred choice for applications that demand the highest level of protection and performance.

PFA Lining for Superior Chemical Resistance : The interior surfaces are lined with PFA, offering exceptional resistance to corrosive chemicals, acids, alkalis, and solvents, which extends the valve's lifespan and prevents degradation.

Flanged End Connections : The flanged ends provide secure, stable connections and ensure a leak-proof seal, suitable for high-pressure systems and applications requiring reliable performance.

Full Port Design : The full bore construction reduces pressure drop and promotes efficient fluid flow, enhancing overall system performance.

Tight Shutoff Capability : The ball valve’s design enables a bubble-tight seal, preventing leaks and ensuring safe operation, even with hazardous media.

Durable Construction : The valve body is made from corrosion-resistant materials, with PFA lining adding an extra layer of protection, making it suitable for prolonged exposure to aggressive chemicals.

Ease of Operation : The valve’s design allows for smooth and efficient manual or automated operation, requiring minimal torque to open and close.

| Valve Details: | |

|---|---|

| Model | BVPFA |

| Operation | Lever / Gear / Phenumatic |

| Size | 25 MM to 200 MM |

| Body | WCB / CF8 / CF8M / CF3M |

| Ball with Shaft | WCB / SS 304 |

| Seal | PTFE / GFT |

| Working Temperature | Upto 180- 230°C |

| Working Pressure | as per 150# |

| End Connection | Flanged End to ASME B16.5 RF (150#) |

Chemical Processing : The PFA lining provides protection against highly corrosive chemicals, making this valve ideal for controlling aggressive acids, bases, and other chemicals in processing plants.

Pharmaceutical Manufacturing : The valve’s non-reactive lining is suitable for pharmaceutical applications where maintaining purity and resisting corrosion from various solvents and chemicals is essential.

Water Treatment : Commonly used in water treatment facilities for handling corrosive media, including chlorine and other chemical additives, the valve provides safe and reliable flow control.

Food and Beverage : The PFA lining meets hygienic standards, making it suitable for handling chemicals and cleaning agents commonly used in food and beverage processing.

Pulp and Paper : This valve is used in pulp and paper production for handling bleaching agents, caustic solutions, and other chemicals, providing resistance to corrosion and ensuring process reliability.

"REGENT" is a leading Manufacturer and Exporter of Hand Lever Operated 3 Piece Design FORGED Ball Valve with Solid Ball Screwed & Socket Weld 800#.

| Valve Details: | |

|---|---|

| Design | 3 Piece design |

| Operation | Lever |

| Size | 1/2" to 2” (15mm to 50mm) |

| Design std. | BS EN 17292 |

| Material | A105N, F304, F316 |

| Pressure / Temp | ASME B 16.34 |

| Testing Std. | BS 12266-1 |

| Construction | Bolted |

| Pressure rating | ASME 800# |

| End Connection | Screwed, Socket Weld, Butt-Weld |

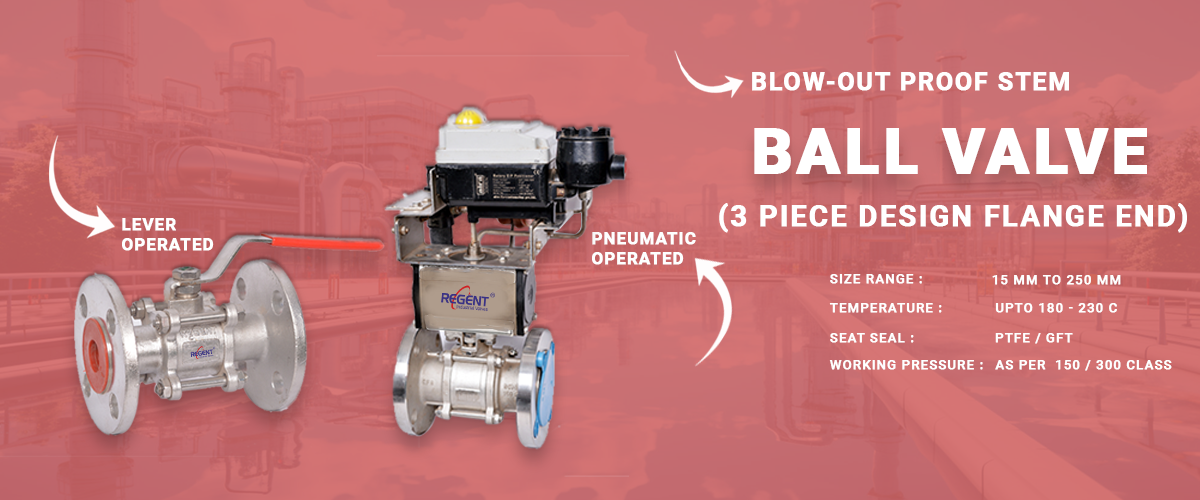

The 3 Piece Design Flange End Valve is meticulously engineered to meet the demands of various industrial applications requiring reliability, easy maintenance, and robust flow control. This valve features a three-piece body construction, allowing for effortless disassembly and reassembly without removing the entire valve from the pipeline. Its flanged end design ensures a secure and stable connection, making it ideal for high-pressure systems. This valve is suitable for handling a wide range of fluids, including corrosive and viscous materials, while providing excellent durability and performance.

The 3 Piece Design Flange End Valve is a dependable and efficient solution for industries requiring high performance and reliability in fluid control. Its durable design, convenient maintenance features, and secure connections make it an ideal choice for a wide range of applications, ensuring optimal performance in demanding industrial environments.

Three-Piece Body Construction : The three-piece design simplifies maintenance and servicing, allowing operators to access internal components easily without needing to disconnect the valve from the piping system.

Flanged End Connections : The flanged ends provide robust and secure connections, ensuring leak-proof performance and stability in high-pressure applications.

Full Bore Design : The full bore construction minimizes pressure drops and ensures maximum flow efficiency, making it suitable for a variety of applications requiring high flow rates.

Durable Materials : Constructed from high-quality materials such as stainless steel or carbon steel, the valve is designed to withstand harsh conditions and resist corrosion.

Versatile Sealing Options : The valve can be equipped with different sealing materials to handle a wide variety of fluids, including corrosive chemicals, steam, and oils.

User-Friendly Operation : Designed for smooth and efficient operation, the valve requires minimal effort to open and close, making it user-friendly in various settings.

| Valve Details: | |

|---|---|

| Model | BV-3P/D |

| Operation | Lever / Gear / Pneumatic / Control type |

| Size | 15 mm to 250 mm |

| Design | Investment casting 3-piece design -150 class, blow-out proof stem, floating ball, full bore ball valves |

| Design & Manufacturing Standard | BS 5351 (BS EN ISO 17292) |

| Inspection & Testing Standard | BS 6755 Part I |

| Body | WCB / CF8 / CF8M / CF3M |

| Ball | AISI 304 / 316 / 316L |

| Seat Seal | PTFE / GFT |

| Lever | Cast steel / Stainless steel with PVC sleeve |

| Working Temperature | Upto 180 - 230°C |

| Working Pressure | as per 150# / 300# |

| End Connection | Flanged end to ASME B16.5 RF (150# / 300#) |

| Actuator Details: | |

|---|---|

| Method of Transmission | Double rack and pinion type |

| Actuation | Double acting - Air to open, air to close; Fail safe - Stay put |

| Body Material | Extruded aluminium, hard anodized |

| Caps and Rack | Aluminium pressure die cast |

| Pinion | EN 8 |

| Seals | Buna-N |

| Air Pressure | Normal air supply pressure: 5 kg/cm2 Max. air supply pressure: 7 kg/cm2 |

| Actuator Design | ISO 5211 (Actuator can be quickly and easily mounted) |

| Rotation | 90° – Quarter turn |

Chemical Processing : Ideal for controlling the flow of aggressive chemicals, acids, and solvents, the valve’s durable construction and leak-proof design ensure safe and reliable operation.

Oil and Gas : Widely used in oil and gas applications, it effectively manages the flow of crude oil, natural gas, and other hydrocarbons under high pressure.

Pharmaceutical Manufacturing : The valve meets stringent hygiene and quality standards, making it suitable for pharmaceutical applications where maintaining purity is crucial.

Food and Beverage : Its corrosion-resistant materials and easy maintenance make it an excellent choice for food and beverage processing, ensuring compliance with health and safety regulations.

Water Treatment : The valve is commonly used in water treatment facilities for managing the flow of potable water, chemicals, and wastewater, offering reliability in various conditions.

The 1 Piece Design Screwed End Ball Valve is a compact and efficient valve ideal for applications requiring tight shutoff and reliable performance in a wide range of industrial environments. Designed with a single-piece body and screwed end connections, this valve provides a secure and leak-proof seal, making it suitable for both high and low-pressure systems. Its simple design ensures ease of installation, maintenance, and operation, while offering durability and versatility in handling various types of fluids.

The 1 Piece Design Screwed End Ball Valve is an excellent solution for industries seeking a compact, reliable, and cost-effective valve. With its sturdy single-piece body, secure threaded connections, and versatile application range, this valve ensures efficient flow control and dependable shutoff in both industrial and commercial settings.

1 Piece Body Construction : The single-piece body design enhances structural integrity, reducing potential leak points and providing a robust and compact valve body.

Screwed End Connections : Equipped with screwed (threaded) ends, the valve offers easy installation and secure connections, making it a great choice for systems that require quick and simple setup.

Full Port Design : The full port construction ensures minimal pressure drop across the valve, allowing for efficient flow and optimal performance.

Tight Shutoff : The ball valve design provides a bubble-tight seal, preventing leakage and ensuring reliable shutoff even under varying pressure conditions.

Corrosion-Resistant Materials : Constructed from high-quality materials, the valve body and components are resistant to corrosion, extending its lifespan and suitability for a variety of media.

Low Torque Operation : The valve is designed for smooth and easy operation, requiring minimal torque to open and close, which enhances user convenience.

| Valve Details: | |

|---|---|

| Model | BV-1P/D |

| Operation | Lever |

| Size | 6 MM to 80 MM |

| Design | Investment casting, 1-piece design, full bore, blow-out proof stem, floating ball, soft-seated, non-fire safe design |

| Design & Mfg. Std. | BS 5351 (BS EN ISO 17292) |

| Inspection & Testing Std. | BS 6755 part i |

| Body | CF8 / CF8M / CF3M |

| Ball | AISI 304 / 316 / 316L |

| Seat Seal | PTFE |

| Working Temperature | Upto 1800 C |

| Working Pressure | as per 150# |

| End Connection | Screwed to BSP / BSPT / NPT |

Water Treatment and Plumbing : Ideal for water systems, the valve provides dependable shutoff and control for water and other non-corrosive fluids, commonly used in plumbing installations.

Chemical Processing : Suitable for handling a variety of chemicals and solutions, this valve is a reliable choice for low-pressure applications in chemical plants where threaded connections are preferred.

HVAC Systems : Used in heating, ventilation, and air conditioning systems to control water flow, the valve’s compact design allows for easy installation in tight spaces.

General Industrial Applications : The valve is widely used across industries for applications that require a robust, leak-proof, and manually operated valve with a simple design.

Agriculture and Irrigation : Commonly used in irrigation systems, the valve allows for precise flow control, ensuring efficient water distribution for agricultural needs.

When it comes to working with fluids under high pressure, high temperature, or possessing aggressive properties, modal selection of a valve for performance and safety reasons comes into play and becomes potent. As for heavy-duty industries, such as the oil and gas, petrochemical, power plants, water treatment plants and fabrication industries, ball valves serve a quintessential purpose by providing control over the flow. Therefore, one has to pay attention when selecting an appropriate Ball Valve Manufacturer for the needs of any industry.

Regent Hitech Private Limited, however, is one of the few elite companies that can provide structural solutions, exclusively designed for extreme industrial conditions, in the most elegant manner. Let us over explain what brands have to do so that the customer believes in their warranties and claws seven of their signatures on the products, and then what brands develop which products when there is a purposeful heavy-duty intervention for Regent Hitech Private Limited.