The contemporary industrial processes are significantly based upon the accurate flow control in order to guarantee safety, efficiency and consistency of the performance. Control valves are important devices used to control the flow, pressure, and temperature of liquid and gaseous systems in industries. Since the power plants up to the chemical processing units, the need to have a high quality of flow control solutions has been on the increase. A stable Industrial Control Valve Manufacturer is chosen to ensure that the operation is stable and the downtime is minimized. Regent Hitech Private Limited has gained a reputation in this field, and it has been providing engineered solutions to valves, which fit in a wide variety of industrial applications. Highly performance oriented and also with durability and compliance, the company has industries backed by valves that are produced and made to withstand the performance and operating conditions. With such technical support and the current manufacturing trends, Regent Hitech Private Limited will make sure that all the products provide long-term value and consistent performance in the high-quality applications.

An Industrial Control Valve Manufacturer is a professional engineering firm that designs, produces and tests valves to control the variables of flow rate, pressure and temperature of processes of an industrial system. These manufacturers take mechanical engineering, material science and process knowledge to provide dependable valve solutions. A manufacturer is not only a person involved in production but also in the analysis of the usage, choice of materials, exact machining, and strict tests. The qualified Manufacturer of an Industrial Control Valve is one who guarantees that the valves will work correctly at the extreme pressure, temperature, and corrosive environment. It should have engineering excellence and tight quality control to repeat performance and operational safety. In Regent Hitech private limited, all the valves are designed keeping in mind accuracy, economy, and performance in accordance to the industry standards, and hence the company is a reliable supplier of vital flow control systems.

Globe control valves are widely used for precise flow regulation in high-pressure and high-temperature applications. Their linear motion design allows accurate throttling and stable control. Regent Hitech Private Limited manufactures globe valves that ensure reliable performance, minimal leakage, and long service life, making them suitable for power generation, oil and gas, and chemical processing industries.

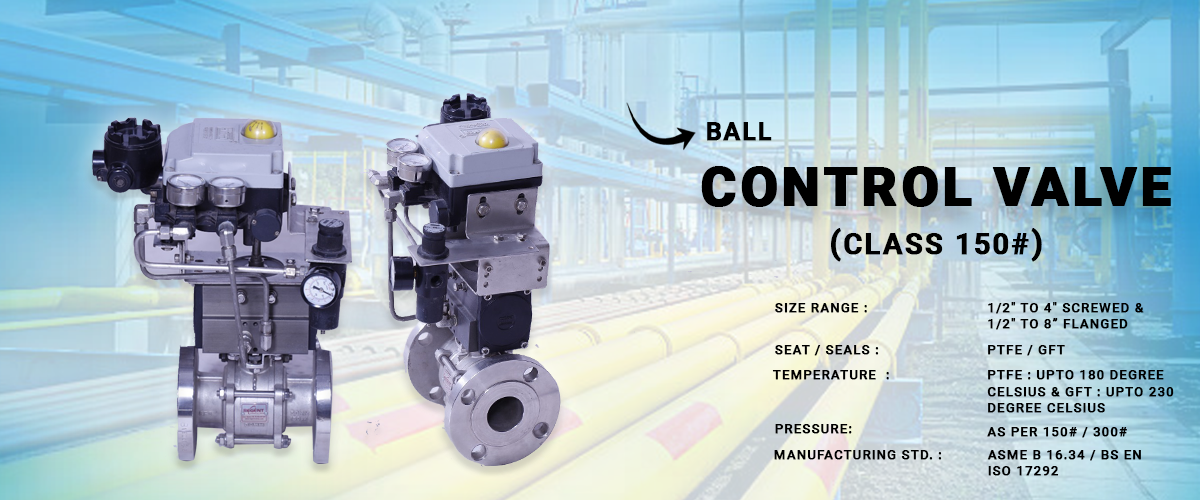

Ball control valves are known for quick operation and excellent sealing capability. These valves are ideal for on-off and throttling applications where tight shut-off is required. As an experienced Industrial Control Valve Manufacturer, Regent Hitech Private Limited delivers ball valves designed for durability, smooth operation, and compatibility with automated control systems.

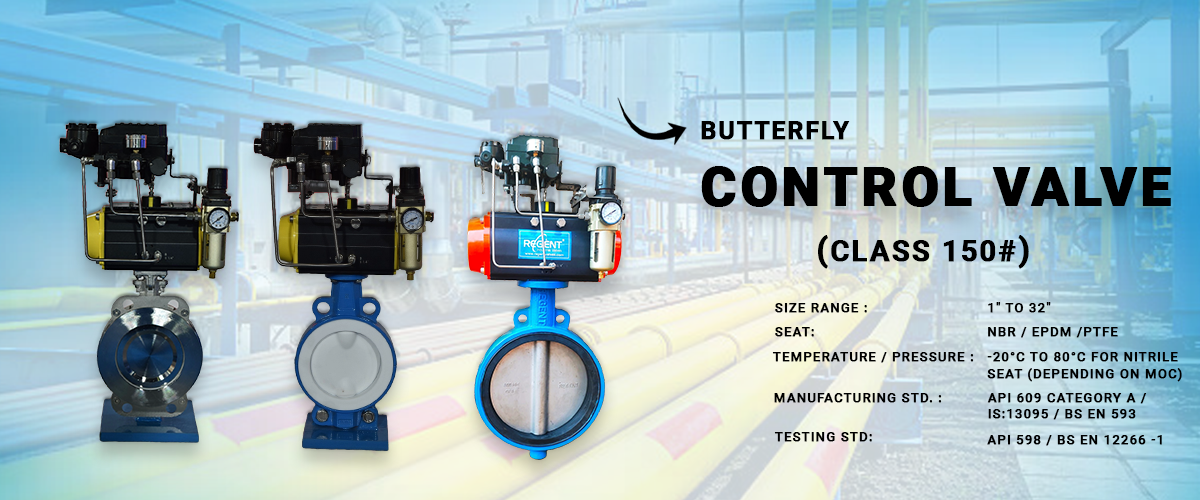

Butterfly control valves offer compact design, cost efficiency, and effective flow control for large-diameter pipelines. They are commonly used in water treatment, HVAC, and industrial utilities. Regent Hitech Private Limited produces butterfly valves that provide low torque operation, high reliability, and consistent performance across varying process conditions.

Regent Hitech Private Limited serves a diverse industry that involves proper and valuable flow control solutions. Being a reliable manufacturer of Industrial Control Valves, the company provides facilities in oil and gas where performance and safety is paramount. These valves are used in the control of steam and fluids in a power plant in extreme conditions. They are used in chemical and petrochemical industries to work with corrosive and dangerous media. The treatment systems of water and wastewater require efficient flow control valves and reliability of the systems. Hygienic designs of valves are beneficial to the food and beverage industry whereas precision control by pharmaceutical manufacturers ensures that products are of good quality. Valves are engineered to serve the industry applications in accordance with operational needs and operational compliances.

The selection of the appropriate Industrial Control Valve Manufacturer influences the efficiency of the system and the reliability of its work directly. The unique features of Regent Hitech Private Limited include a good engineering background and customer focus. The company has a broad product line with good manufacturing facilities and qualified technical people. Strict quality assurance measures set up to make sure all the valves address the performance and safety requirements. Regent Hitech Private Limited is dedicated to the idea of customization to fit the exact application requirements offering the customized solution to the complicated industrial process. The competitive pricing, delivery on time, and responsive technical support will also increase client confidence. The long term associations with the customers within the industries show that the company is concerned with quality, reliability, and the constant improvement of the industrial flow control solutions.

The production cycle of the Regent Hitech Private Limited is organized and managed to guarantee the regular quality of the product. The company is a long-standing Industrial Control Valve Manufacturer, and this means that it starts by ensuring that its raw materials are carefully chosen, depending on the way they are going to be used. During the production of the products, precision machining and controlled assembly processes are to assure dimensional accuracy and performance reliability. The individual valves are tested through a series of rigorous tests such as pressure, leakage and functional tests. Adherence to the international standards and internal quality standards ensures the safety and sustainability of the operations. The constant tracking and recording of all steps of production also serves to ensure the presence of traceability and reliability and so customers have the opportunity to acquire valves that they can count on during crucial use.

Special solutions of valves are demanded in industrial processes. Regent Hitech Private Limited offers both unique design to suit special operating conditions and system requirements. Being a customer-oriented manufacturer of Industrial Control Valves, the company favors actuator integration, automation compatibility, and the choice of special materials. The engineering teams collaborate closely with clients to study parameters of the processes and provide the best valve solutions. This customization functionality will guarantee better system efficiency, fewer maintenance and easy integration with the available control systems.

The use of industrial control valves is necessary to control the flow, pressure, and temperature of complex process systems. An effective Industrial Control Valve Manufacturer is one that provides valves that work correctly in the different applications like fluid distribution, steam control, pressure regulation and safety isolation. These valves improve stability of process, equipments security, and energy saving. They are important in industries to ensure the quality of output and safety of operation. The valves designed by regent Hitech private limited provide reliable operation in the demanding and continuous operating environments.

Modern manufacturing practices are associated with innovation and sustainability. Regent Hitech Private Limited also invests in research and development in order to enhance the performance and efficiency of the valve. The company is a progressive Industrial Control Valve Manufacturer, which is designed in terms of saving on energy, minimizing leakage, and as well as increasing the service life. The sustainable manufacturing practices aid in reducing the effect on the environment and providing long-lasting products that aid responsible industrial development.

Regent Hitech Private Limited is a reliable Manufacturer of Industrial Control Valves that has been able to establish itself as a reliable manufacturer of quality and precision-engineered valve solutions. The company has a high emphasis on performance, reliability, as well as customer satisfaction, and it serves different industries with effective flow control products. Technology, consistency and tailor-made solution makes Regent Hitech Private Limited a reliable choice in achieving sustained success in the industry.

"REGENT" Offers Resilient-seated, butterfly valve for flange mounting to pipelines; concentric disc design; with replaceable liner. Suitable for use in cooling towers, waste-water applications, water treatment, water distribution, dams, gas main and service lines, pressure stations, gas storage tanks, power plants and gas pipelines industry.

ON/OFF Indicator, Solenoid Valve, Electro-Pneumatic Valve Positioner, Limit Switch for ON/OFF Valve Indication at Panel Board, Filter + Regulator Combination with Pressure Gauge.

Due to our proficiency in this field, we are engaged in presenting Control Type Rubber Lined Wafer Type Butterfly Valve. We are presenting these products to customers within given time-frame.

| Valve Details | Description |

|---|---|

| Minimum Order Quantity | 1 Piece |

| Size | 1" to 32" |

| Brand | REGENT |

| End Connection | Wafer Type Suit 150, Table D, E IS 6392 Table 11 (PN 6 / PN 10 / PN 16) |

| Seat | EPDM / PTFE |

| Temperature | -20 to 80 Degree Celsius for EPDM (Depending on MOC) High Temperature On Request |

| Disc | WCB / CF8 / CF8M |

| Seat Leakage | Tight Shut Off |

| Body Type | Short Wafer Type |

| Valve Type | Centric Disc Butterfly Valve with Single Piece Rubber Lined Body |

| Pressure Rating | PN 6 / PN 10 / PN 16 |

| Shaft | AISI 410 / AISI 304 / AISI 316 |

| Body | S.G iron / Cast Iron / WCB / CF8 / CF8M |

| Country of Origin | Made in India |

Production Capacity : As Per Requirement

Delivery Time : 2 - 3 Days

Packaging Details : Plastic Polythene Bag / Corrugated or Wooden Box

“REGENT” Leading Manufacturer, Supplier and Exporter of Pneumatic 3 Piece Design Floating Ball Valve in India. We are also Exporter Pneumatic Ball Valve to worldwide as per customer requirement.

ON/OFF Indicator, Solenoid Valve, Electro-Pneumatic Valve Positioner, Limit Switch for ON/OFF Valve Indication at Panel Board, Filter + Regulator Combination with Pressure Gauge.

| Valve Details | Description |

|---|---|

| Minimum Order Quantity | 1 Piece |

| Ball | ASTM A351 Gr. CF8 / CF8M |

| Body | ASTM A216 Gr. WCB / ASTM A351 Gr. CF8 / CF8M |

| Ends | Screwed to BSP / NPT & Flange end 150# / 300# |

| Leakage Class | Class VI |

| Seals | PTFE / GFT |

| Country of Origin | Made in India |

| Design Standard | ASME B 16.34 / BS EN ISO 17292 |

| Design | 3 Pcs |

| Media | Air / Water / Oil / Gas & Chemical |

| Temperature | PTFE : Upto 180 Degree Celsius & GFT : Upto 230 Degree Celsius |

| Pressure | as per 150# / 300# |

| Brand | REGENT |

| Size | 1/2" to 4" Screwed & 1/2" to 8” Flanged |

Production Capacity : As Per Requirement

Delivery Time : 2 - 3 Days

Packaging Details : Plastic Polythene Bag / Corrugated or Wooden Box

"REGENT" is a manufacturer, exporter, and supplier of V Notch Ball Valve. V-Notch Ball valves are specially used to control the flow rate in pipelines because it has V-Notch inside the valve body. V Notch Ball Valve characterized V ball which is perfectly suited to give a full range of control applications with superior flow control. In small sizes, these control ball valves when compared to globe valves are more compact, lighter in weight, and much less expensive. The V-Notch Ball Valve is also known as V Port Ball Valve and It can sustain up to 10Kg/Cm² pressure & temperature up to 180°C. We use PTFE seals, WCB/CF8/CF8M materials used to make the Body, and CF8/CF8M to make the Ball. Stainless Steel 304 has been used for the Gland plate, Gland L.N. Bolt, Trunnion pin, and bracket fitting bolts. For the Shaft and retainer, we use S.S. 304/S.S. 316. It has a class VI leakage type. It is available in 1” to 10” inches & has flanged ends 150# to 300#.

ON/OFF Indicator, Solenoid Valve, Electro-Pneumatic Valve Positioner, Limit Switch for ON/OFF Valve Indication at Panel Board, Filter + Regulator Combination with Pressure Gauge.

| Type of Valve | V-notch flanged end ball valve |

| Size range | 25mm to 250mm |

| Body | SS 304 / SS 316 |

| Ball | SS 304 / SS 316 |

| Temperature range | ptfe : upto 1800 C / rptfe - 200 |

| working Pressure | upto 10 kg/cm2 |

| manufacturer std. | bs en iso 17292 |

| inspection & testing | asme / fci 70-2 metal seat for uni-direaction flow , soft seat |

| Valve Face To Face Dimension | ASNI B16.10/ DIN 3202/ BS EN 558-1/2 |

| Top Flange Drilling | ASA 150#/ DIN 2632 & 2633/ BS EN 10 TABLE D,E (Customer Specified) |

| Flange Standard Conformity | ASME B16.5 150# |

| Media | Air/ Water/ Oil & Gas |

| End Connection | Flanged End ANSI 150# |

| Leakage Class | Class IV |

Production Capacity : As Per Requirement

Delivery Time : 2 - 3 Days

Packaging Details : Plastic Polythene Bag / Corrugated or Wooden Box

Globe Valves are essential flow control devices commonly used to regulate or stop the flow of liquids, gases, or steam. Featuring a globe-shaped body and a movable disc that seats against a stationary ring, these valves provide precise throttling and flow control capabilities, making them ideal for applications requiring accurate flow regulation and frequent operation.

ON/OFF Indicator, Solenoid Valve, Electro-Pneumatic Valve Positioner, Limit Switch For ON/OFF Valve Indication At Panel Board, Filter + Regulator Combination With Pressure Gauge.

Precise Regulation With High Flow Capacity

Large Type Of Trim Top Operating Designs For Various Duty Conditions.

In Line Repairable Design For Easy Maintenance.

Tight Closure Even In Extreme Operating Conditions.

Multi Action Type Actuator ( Direct / Reverse Acting ).

Wide Range Of Actuators To Meet Different Application.

| Size Range | 25MM to 300MM |

| Temperature Range | Up to 220°C Max |

| Shutoff Rating | Tight Shut Off Leakage Class - 6 |

| Body Style | 2 WAY Globe Type |

| Flange Drilling | 150#, 300# |

| Body Materials | WCB / CF8 / CF8M |

| Stem Materials | S. S - 304 / S. S - 316 |

| Seat Materials | PTFE / CFT / GFT |

| Plug Materials | S. S - 304 / S. S - 316 |

| Design Standard | BS 6697 |

| End Connection | Flanged End ASME B 16.5 CL 150# / 300# |

| Testing Standard | FCI 70 - 2 |

| Face To Face | ISA - 75.03, IEC 534 - 3 |

| Leakage | V to VI / FCI 70 - 2 |

| Applications | Steam / Gas / Water & Air |

Production Capacity : As Per Requirement

Delivery Time : 2 - 3 Days

Packaging Details : Plastic Polythene Bag / Corrugated or Wooden Box