The key to a modern day processing plant is its industrial flow control systems which allow the safe and efficient control of liquids, gases and slurries in pipelines. With water distribution systems and power-process chemical plants, the integrity of flow control equipment has a direct influence on the safety and productivity of the operation. The most important type of valves is the gate valve because of its capability to give full flow or total shut-off with minimal pressure loss. The need to have a reliable Gate Valve Manufacturer has continued to increase as the industries grow, as well as the growth in the number of infrastructure projects. Customers are demanding companies that integrate engineering skills, quality materials, and conformity to international standards. Regent Hitech Private Limited has become a company that people can rely upon in this field by providing durable and high-quality gate valves to a wide variety of industrial needs. The firm serves performance-driven, durable and customer satisfaction-oriented industries with minimal products having long-term and effective flow control demands.

A gate valve manufacturer is an industrial company, which designs, engineers, manufactures, and tests gate valves, which are used to regulate the flow of fluids in the pipelines. The key task of such a manufacturer is to be sure that each of the valves performs reliable isolation, smooth working and long service under severe conditions. To sustain accuracy and uniformity, a professional Gate Valve Manufacturer is investing in high-end engineering equipment, skilled labor force and up-to-date machines. The precision of machining, quality standards, and strict inspection procedures are needed and required to avoid leakage, pressure loss or failure of operation. Manufacturers deal with a diverse industry such as oil and gas, water management, power generation, chemicals and process industries. With both standard and customized solutions, a trustworthy Gate Valve Manufacturer would be a frequent collaborator of any industrial project, which will require safety, efficiency, and adherence.

Regent Hitech Private Limited manufactures a wide range of gate valves to meet different pressure ratings, materials, and industrial applications. As a reliable Gate Valve Manufacturer, the company focuses on durability, precision, and performance.

○ Widely used in water supply, irrigation, and wastewater systems

○ Manufactured from high-quality cast iron for corrosion resistance

○ Designed for smooth operation and long service life

○ Ideal for low-pressure and large-diameter pipelines

○ Suitable for high-pressure and high-temperature applications

○ Commonly used in oil & gas, power plants, and refineries

○ Forged steel construction ensures superior strength and reliability

○ Performs efficiently under extreme operating conditions

○ Designed for general industrial flow control systems

○ Offers excellent sealing and structural integrity

○ Used in chemical, petrochemical, and process industries

○ Balances performance, durability, and cost-effectiveness

Each valve is engineered to meet industry standards, reinforcing Regent Hitech Private Limited’s reputation as a dependable Gate Valve Manufacturer.

The production of Regent Hitech Private Limited is designed in such a way that the quality and precision are maintained. It starts with elaborate design and engineering, and technical requirements, pressure, and requirements of application are scrutinized properly. Raw materials of high grade are used so as to promote strength, corrosion resistance, and durability, controlled casting or forging is then carried out. Precision machining is used to assure the correct dimensions, finishes and correct sealing surfaces. The process of assembly is done by trained technicians following standard procedures to ensure uniformity. All the valves are extensively tested (pressure, leakage, as well as functional) to ensure that they work in the actual conditions of operation. International standards of compliance including API, ANSI, and DIN are followed in the production strictly. This is a systematic strategy that helps the company to become a reliable Gate Valve Manufacturer which provides products that are of global expectations.

The selection of the appropriate partner is critical to the presence of the dependable flow control solutions, and Regent Hitech Private Limited is unique in a variety of ways. The company has modern manufacturing plants furnished with modern machinery and testing equipments. A quality engineering staff will provide constantly high design, performance, and efficiency. Customization allows the client to get valves that are suited to their pressure, size and use requirements. The solutions are affordable to both domestic and international customers because the pricing is competitive, without sacrificing the quality. Customers are also assured of timely delivery and responsive services. Having an established history of success in various industries, the organization has earned a good reputation as a favorite Gate Valve Manufacturer of the projects which require reliability, compliance, and long-term benefits.

The regent Hitech Private Limited produces gate valves that are utilized in various industries. They offer safe isolation in petroleum and gas production both upstream and downstream. These valves are used in water treatment facilities and wastewater treatment facilities to ensure reliable flow control and to have low maintenance. The gate valves are used to control the use of steam, water, and auxiliary systems in power generation facilities. They are useful in chemical and petrochemical industries that can manage the corrosive and high-pressure fluids. Precision-engineered valves are used in pharmaceutical and food processing units to ensure hygiene and integrity of processes. The company is a competent Gate Valve Manufacturer and thus provides solutions that are reliable in a variety of operating conditions.

One of the priorities of the Regent Hitech Private Limited is quality. The company adheres to the quality management systems that are ISO certified in order to ascertain consistency and traceability. All valves are pressure and leakage tested to ensure that they remain safe. The global acceptance is ensured by adherence to accepted standards like API, ANSI and DIN. The employing of strict inspection protocols and documented testing is the evidence of the dedication of the organization to the safety, durability and performance. These actions support its reputation as a conscientious Gate Valve Manufacturer with extreme industrial use.

Regent Hitech Private Limited embodies manufacturing perfection characterized by high standards of accuracy, extreme quality management and customer-oriented solutions. In design to delivery, each and every step is based on reliability and compliance. Having a wide product portfolio, current infrastructure and understanding of the industry, the company has been able to sustain some key areas of the world. Regent Hitech Private Limited through its consistent ability to meet technical and performance standards strengthens its authority and confidence to achieve long term industrial success as a manufacturer of Gate Valves.

The Forged Steel Gate Valve is a crucial component in various industrial applications, designed for efficient on-off control of fluid flow. Made from high-quality forged steel, these valves offer exceptional strength, durability, and resistance to high pressures and temperatures. Their robust construction makes them suitable for a wide range of demanding environments, including oil and gas, chemical processing, and power generation.

The Forged Steel Gate Valve is an excellent choice for industries requiring reliable and efficient flow control. With its robust construction, minimal pressure drop, and versatility in applications, this valve ensures optimal performance and safety in various demanding environments. Whether in oil and gas, chemical processing, or water treatment, the forged steel gate valve stands out as a dependable solution for managing fluid flow.

Forged Steel Construction : Manufactured from high-grade forged steel, these valves are designed to withstand extreme conditions, ensuring a longer lifespan and reduced risk of failure under high-pressure applications.

Gate Design : The gate mechanism provides a straight-through flow path, minimizing pressure drop and turbulence. When fully open, the valve offers unrestricted flow, making it suitable for applications requiring high flow rates.

Reliable Sealing Performance : The gate valve provides a tight seal when closed, preventing leakage and ensuring the safe handling of fluids. The resilient seating materials enhance sealing performance in both high-temperature and corrosive environments.

Various End Connections : Available with different end connections such as flanged, threaded, or butt-weld, the forged steel gate valve can be easily integrated into various piping systems, ensuring compatibility with existing infrastructure.

Robust Design for High Pressure and Temperature : Engineered to operate effectively in extreme conditions, these valves maintain their integrity under high pressure and temperature, making them ideal for demanding applications.

| Valve Details: | |

|---|---|

| Operation | Handwheel |

| Size | 15 MM To 50 MM |

| Class | 800# / 1500# / 2500# |

| Body / Bonnet | Forged Steel (A105 / F304 / F316) |

| trim | SS 410 |

| End Connection | Threaded / Socket Weld / Butt Weld Ends |

| Design std. | API 602 |

| testing std. | API 598 |

| pressure / temp. | Asme b 16.34 |

Oil and Gas Industry : Widely used in oil and gas pipelines for controlling the flow of crude oil, natural gas, and other hydrocarbons, ensuring safe and efficient operations.

Chemical Processing : The forged steel gate valve is essential for managing the flow of corrosive and hazardous chemicals in processing plants, providing reliable operation in demanding conditions.

Power Generation : Utilized in power plants for regulating water, steam, and other fluids, the valve ensures efficient control of processes critical to energy generation.

Water and Wastewater Treatment : Employed in water treatment facilities to manage the flow of water and sludge, the valve helps maintain efficient and reliable operations in various stages of water purification.

Mining and Mineral Processing : Ideal for controlling the flow of slurries and abrasive materials in mining applications, the robust construction of forged steel gate valves ensures durability in harsh environments.

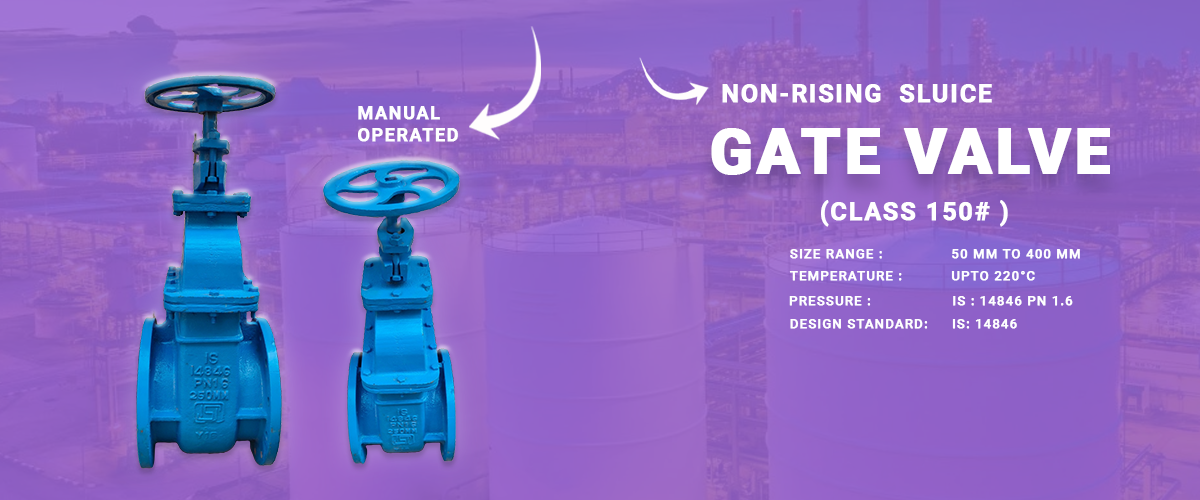

A CI Sluice Gate Valve is a type of valve commonly used for controlling the flow of water or other liquids in large pipelines, primarily in water treatment, irrigation, and wastewater management systems. These valves are essential in regulating the flow in open channels, dams, or reservoirs. The design of the sluice gate valve typically includes a flat or wedge-shaped gate that is raised or lowered to control the flow of fluids.

| Valve Details: | |

|---|---|

| Body | Cast Iron / Ductile Iron |

| Bonnet/Cap | Cast Iron / Ductile Iron |

| Stuffing Box | Cast Iron / Ductile Iron |

| Gland | Cast Iron / Ductile Iron |

| Wedge | Cast Iron / Ductile Iron |

| Wedge & Body Ring | 13% CR. |

| Drilling | As Per IS: 1538 |

| Pressure Rating | PN 1.6 |

Water Treatment : Used extensively in water treatment plants for controlling the flow of potable water, wastewater, and other fluids. Gate valves provide reliable operation in these systems, ensuring efficient flow management.

Oil and Gas Industry : Essential for controlling the flow of crude oil, natural gas, and other hydrocarbons in pipelines and processing facilities. The gate valve’s high-pressure capability and robust design make it ideal for the oil and gas sector.

Chemical Processing : Employed in chemical plants to manage the flow of corrosive or hazardous chemicals, gate valves are constructed from materials that resist chemical attack, ensuring safe operation.

Power Generation : Widely used in power plants to regulate water, steam, and other fluids necessary for power production, gate valves offer efficient flow control and reliable shut-off capabilities.

Mining and Mineral Processing : Ideal for handling abrasive slurries and materials in mining applications, the gate valve’s durability and tight sealing ability make it a dependable choice in these harsh environments.

The Gate Valve (150# / 300#) is a widely used valve type designed primarily for on-off control of fluid flow. Known for its simplicity, durability, and minimal flow resistance, the gate valve is used in a wide range of industrial applications, including water treatment, oil and gas, and chemical processing. This valve operates by raising or lowering a flat or wedge-shaped gate to control the flow of liquids and gases.

The Gate Valve (150# / 300#) is a versatile and reliable solution for industries requiring effective flow control and shut-off capabilities. Its robust design, minimal pressure drop, and suitability for various applications make it an essential component in fluid control systems. Whether in water treatment, oil and gas, or chemical processing, the gate valve provides efficient performance and long-lasting durability for a wide range of demanding industrial applications.

Straight-Through Flow Design : When fully open, the gate valve allows for unobstructed flow, resulting in minimal pressure drop and turbulence, making it ideal for applications where high flow efficiency is required.

Reliable Shut-Off : The gate valve provides a tight seal when fully closed, preventing leaks and ensuring reliable flow isolation. This feature makes it suitable for applications where complete flow stoppage is essential.

Versatile Material Options : Available in a variety of materials, including stainless steel, cast iron, brass, and carbon steel, gate valves can be customized to handle different types of fluids, from potable water to corrosive chemicals.

Wedge and Parallel Gate Options : The gate can be either a wedge-shaped or parallel design, with each type offering specific benefits. The wedge type provides a tighter seal, while the parallel gate is ideal for high-pressure applications.

Manual, Electric, or Pneumatic Actuation : Gate valves can be operated manually with a handwheel or outfitted with electric or pneumatic actuators for automated operation, offering flexibility in control options.

| Valve Details: | |

|---|---|

| Operation | Handwheel / Gear Operated |

| Size | 25 MM To 800 MM |

| Class | 150# / 300# |

| Body / Bonnet | ASTM A Gr. 216 WCB / CF8 / CF8M |

| Trims | 13% Cr. |

| Stem | SS 410 |

| End Connection | Flanged End To ASME B 16.5 150# / 300# RF |

| Design / Mfg. Std. | API 600 |

| Inspection & Testing Std. | API 598 |

| Face To Face | ASME B 16.10 |

Water Treatment : Used extensively in water treatment plants for controlling the flow of potable water, wastewater, and other fluids. Gate valves provide reliable operation in these systems, ensuring efficient flow management.

Oil and Gas Industry : Essential for controlling the flow of crude oil, natural gas, and other hydrocarbons in pipelines and processing facilities. The gate valve’s high-pressure capability and robust design make it ideal for the oil and gas sector.

Chemical Processing : Employed in chemical plants to manage the flow of corrosive or hazardous chemicals, gate valves are constructed from materials that resist chemical attack, ensuring safe operation.

Power Generation : Widely used in power plants to regulate water, steam, and other fluids necessary for power production, gate valves offer efficient flow control and reliable shut-off capabilities.

Mining and Mineral Processing : Ideal for handling abrasive slurries and materials in mining applications, the gate valve’s durability and tight sealing ability make it a dependable choice in these harsh environments.